Key Takeaways

Implementing and scaling Product Information Management (PIM) software is critical for modern e-commerce, retail, and manufacturing businesses, but it comes hand in hand with operational, technical, and organizational challenges.

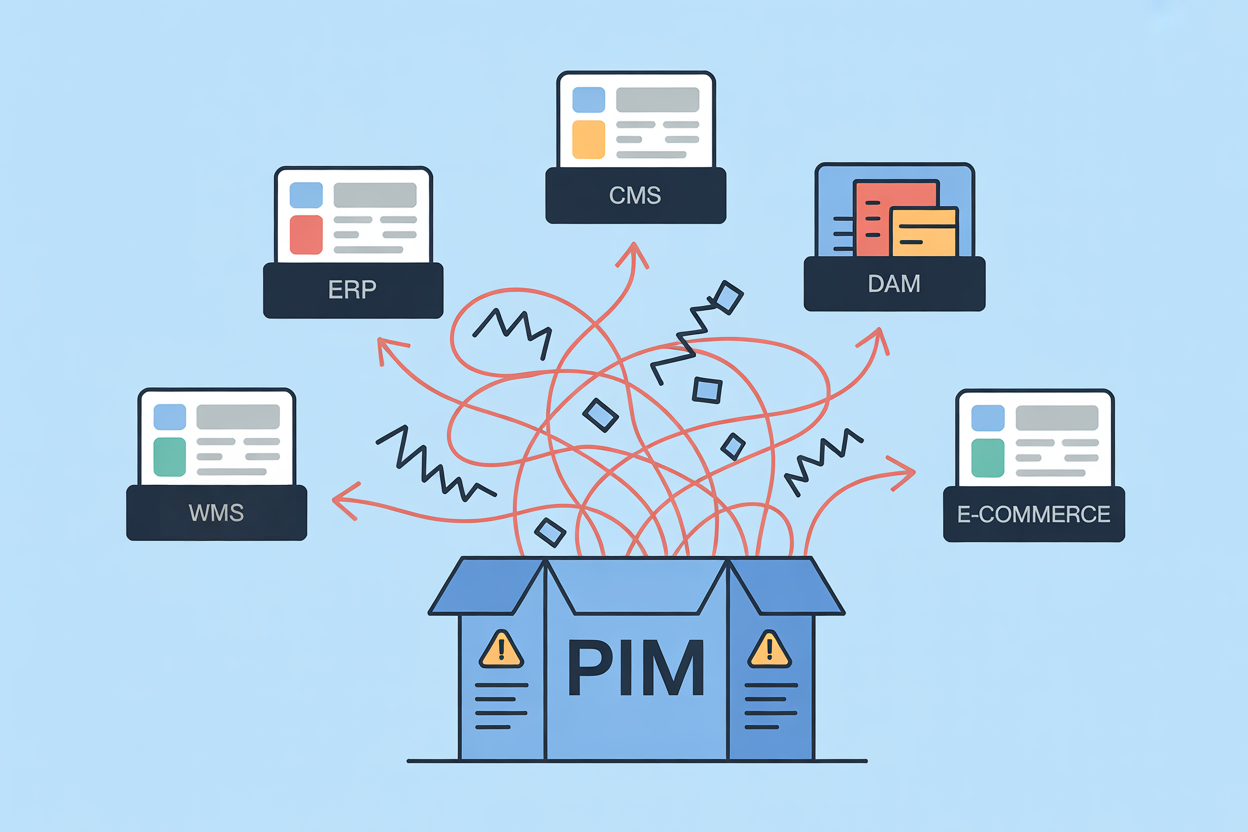

Major Challenges in Implementing and Scaling PIM Software:

- Poor input data quality from legacy systems and suppliers

- Complex integration scenarios with ERP, CMS, DAM, and e-commerce systems

- Low user adoption and acceptance

- Unclear implementation goals and strategy

- Hidden costs beyond licensing

- Unexpected limitations within scalability and flexibility

- Weak collaboration between different functional teams.

This article explores these challenges in detail and provides practical strategies to overcome them and achieve long-term value.

The Double-Edged Sword of Product Data

Launching a new product across multiple channels often involves dealing with fragmented product data spread across webshops, marketplaces, print catalogs, spreadsheets, and legacy systems. The result is inconsistent pricing, missing attributes, and outdated descriptions, commonly referred to as product data chaos.

Product Information Management (PIM) software is designed to reduce this complexity by serving as a central and reliable source for all product information. For modern organizations, especially in e-commerce, retail, and manufacturing, PIM has shifted from a “nice-to-have” to a necessary system for handling growing product portfolios, launching products faster, and maintaining consistent information across all customer touchpoints.

However, as is often the case with enterprise software, PIM is not a quick or effortless fix for all product data problems. PIM brings clear benefits, but implementing and scaling it comes with real challenges. Knowing these challenges early helps ensure long-term success.

This article breaks down the most common PIM implementation challenges and how to overcome them effectively.

The Main PIM Software Challenges

Getting the Poor-Quality Product Data from the Start

Most organizations start a PIM project by importing product data from multiple legacy sources, ERP systems, supplier spreadsheets, shared drives, or old CMS tools. This data is often incomplete, duplicated, or defined differently across teams. For example, the same product may appear multiple times with different SKUs, missing dimensions, or conflicting descriptions.

Because these issues have built up over the years, teams frequently assume their data is “good enough” until it is exposed in one central system. The result is a classic garbage-in, garbage-out situation: the PIM reflects and amplifies existing data problems instead of fixing.

The Solution

-

Data audit and cleansing

Before going live, teams perform a structured review of existing product data to identify duplicates, missing attributes, and inconsistencies. Common steps include standardizing units of measure, aligning attribute definitions, and cleaning up product naming conventions. -

Clear data governance

Responsibilities are defined upfront, so ownership is clear. For example, Product teams manage technical attributes, while Marketing owns product descriptions. Validation rules and approval workflows are enforced directly in the PIM system. -

Automation and validation

Mandatory fields, format checks, and automated rules prevent incomplete or incorrect data from being saved or published. This ensures that data quality remains stable over time, rather than degrading again.

Many advanced PIM solutions, for example AtroPIM, enforce required attributes at the data model and workflow level. Products cannot be published if mandatory fields are missing, and completeness indicators are lower than expected. This actively encourages administrators and product teams to enrich product records fully rather than postponing data quality fixes.

By treating data quality as a foundational step rather than an afterthought, organizations turn PIM into a dependable system rather than a centralized collection of unresolved data issues.

System Integration Complexity

PIM is often introduced into an already complex system landscape that includes ERP, e-commerce platforms, CMS, DAM, and sometimes multiple regional systems. In many projects, integration is treated as a technical afterthought rather than a core design task. As a result, teams discover too late that product data is owned by different systems, updated at different times, and required in different formats.

For example, prices and stock levels may live in the ERP, marketing content in a CMS, and images in a DAM. Without clear rules, teams resort to manual exports, duplicated logic, or custom scripts that are hard to maintain. Over time, these workarounds create fragile integrations and reintroduce data silos.

The Solution

-

Define integration scenarios early

Before implementation, teams clearly decide which system owns which data. For example, the ERP owns pricing and availability, while the PIM owns product content and enrichment. -

Map data flows and interfaces

Data flows, update frequencies, and APIs are documented in detail so every system interaction is predictable and testable. -

Use standardized APIs and middleware

Instead of point-to-point integrations, teams rely on APIs or middleware layers that decouple systems and simplify future changes. -

Roll out integrations in phases

Integrations are tested in pilot scenarios before full rollout, reducing risk and making issues easier to isolate.

By treating integration as a strategic design task rather than a technical detail, organizations ensure PIM fits cleanly into their system landscape and supports long-term scalability.

User Resistance and Adoption Challenges

When teams switch from familiar tools like spreadsheets to a PIM system, many employees resist the change because it alters their daily routines and introduces new processes. This isn’t just anecdotal, as poor user adoption is a leading reason that enterprise software projects fail. Research suggests that up to 70% of software implementations fail due to low user adoption, and 83% of executives cite getting staff to use new systems as a major challenge.

The Solution

-

Engage key stakeholders early

Include representatives from Marketing, Sales, Product, and E-commerce in planning and requirement sessions so they feel ownership of the new system and its workflows. -

Provide role-based training

Tailor training programs to real daily tasks instead of generic overviews. This helps staff understand why and how PIM improves their workflow. -

Focus on usability and support

Choose solutions with intuitive interfaces and clear navigation, and provide ongoing support channels rather than one-off training sessions.

Addressing user resistance as an integral part of the PIM project, not an afterthought, greatly increases the likelihood that teams will adopt and benefit from the system in practice.

Lack of Clear Vision & Strategy

Many PIM projects begin with a broad goal, such as “improving product data,” but lack concrete, measurable objectives. Without a clear definition of what success looks like, requirements continue to grow during implementation. Teams add features, workflows, and integrations that are not immediately necessary, which increases complexity and slows delivery.

In practice, this often results in a system that is technically sophisticated but poorly aligned with actual business priorities.

The Solution

-

Define clear business objectives upfront

PIM goals are directly tied to measurable KPIs, such as reducing time-to-market by 30 percent, increasing product data completeness to 99 percent, or cutting manual data maintenance effort in half. -

Start small and scale deliberately

Teams follow a “crawl, walk, run” approach by launching with a minimum viable PIM focused on core product data and a limited number of channels. Additional features, workflows, and integrations are added only after the initial setup delivers clear value.

By treating PIM as a strategic initiative with clear goals and phased execution, organizations avoid unnecessary complexity and ensure the system supports real business outcomes.

Misunderstanding the Real Cost of PIM Implementation

Many organizations focus primarily on PIM licensing costs when planning a project. In reality, licensing is only a fraction of the total cost. Significant effort is required for data cleansing, system integration, configuration, user training, and ongoing support. These costs are often discovered late, after the project is already underway.

The Solution

-

Plan for the full total cost of ownership

Budgets include implementation services, data preparation, training, integrations, and long-term support, not just software fees. -

Establish cross-functional ownership

A dedicated PIM team is formed with representatives from Product, Marketing, E-commerce, and IT. This ensures realistic workload planning and continuous improvement of the system.

By accounting for real costs upfront and assigning shared ownership, organizations avoid financial surprises and set their PIM initiative up for long-term value creation.

The Scaling Bottleneck

Many PIM systems perform well during initial rollout, when product catalogs are limited, and only a small number of users are active. Problems often emerge later as the business expands. Adding new product lines, entering new markets with multilingual content, or onboarding more internal users can significantly increase system load.

A common real-world scenario is launching internationally. Suddenly, each product requires multiple language versions, market-specific attributes, and additional channels such as regional marketplaces or print catalogs. If the PIM was not designed to scale, performance degrades, and teams begin exporting data into spreadsheets again to avoid slow systems.

The Solution

-

Choose a scalable architecture

Cloud-native PIM solutions designed for elasticity handle growing data volumes and concurrent users more reliably. -

Use flexible data models

A PIM should support new product types, attributes, and relationships without heavy reconfiguration or custom development. -

Design for omnichannel distribution

The system must support consistent data syndication across webshops, marketplaces, social commerce, and print without manual duplication.

By selecting a PIM with growth in mind, organizations avoid replacing one bottleneck with another as the business evolves.

Keep in mind that functional scalability could double or even triple your total costs.

The Communication Gap

Product data rarely originates inside the organization alone. Suppliers often provide specifications, images, and compliance information, frequently in inconsistent formats and at different levels of completeness. Internally, Product, Marketing, and E-commerce teams may still work independently, each maintaining their own versions of product data.

For example, a supplier may deliver technical data late or in spreadsheets, while Marketing is already preparing launch content. Without clear workflows, teams either wait, duplicate work, or publish incomplete information.

The Solution

-

Automate supplier data intake

Supplier portals and structured import processes allow external partners to submit data in predefined formats, reducing manual rework. -

Enforce workflows and approvals

Role-based workflows, approval steps, and audit trails ensure that product data is reviewed and completed before publication. -

Standardize without losing flexibility

PIM platforms such as AtroPIM demonstrate how configurable workflows and attribute models can support different teams and suppliers while maintaining consistent standards.

By improving communication with suppliers and enforcing cross-functional collaboration internally, organizations ensure that PIM truly becomes a single, reliable source of product information.